Our Services

Hemp fuels are the real thing and are very sustainable as a solution to our dependence on fossil fuels. Hemp biodiesel are is affordable and efficient to make. They have been around for a very long time as you can see by this statement by Hugh Downs in 1990.

“At one-time hemp seemed to have a promising future as a cornerstone of the fuel industry. When Rudolph Diesel produced his famous engine in 1896, he assumed that the diesel engine would be powered by a variety of fuels, especially vegetable and seed oils. Rudolph Diesel, like most engineers then, believed vegetable fuels were superior to petroleum. Hemp is the most efficient vegetable. In the 1930s the Ford Motor Company also saw a future in biomass fuels. Ford operated a successful biomass conversion plant, that included hemp at their Iron Mountain facility in Michigan. Ford engineers extracted methanol, charcoal fuel, tar, pitch, ethyl-acetate and creosote. All fundamental ingredients for modern industry and now supplied by oil-related industries.” Hugh Downs, 1990

Hemp Ethanol

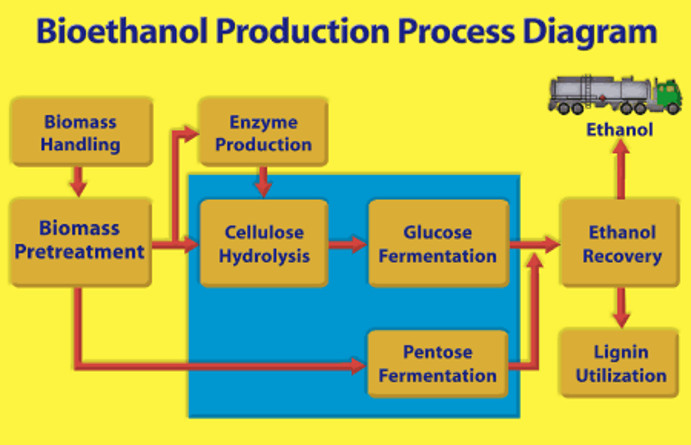

One interesting use for industrial hemp is turning it into ethanol. By definition, ethanol, is a type of alcohol fuel that is distilled from plant material, such as corn. It is important to understand that hemp provides two types of fuel; hemp biodiesel – made from the oil of the hemp seed, and hemp ethanol/methanol – made from the fermented stalk. To clarify further, ethanol is made from such things as grains, sugars, starches, wastepaper & forest products, and methanol is made from woody matter. Through processes such as gasification, acid hydrolysis and enzymes, hemp can be used to make both ethanol and methanol. In the US, Hemp ethanol can be produced for .35 cents per litre plus the cost of the feedstock, with technological improvements and tax credits reducing the price another .25 cents a litre. Hemp Ethanol is a viable solution and should be used to augment our dependence on fossil fuels and in many ways provide for a cleaner more sustainable solution.

Hemp Bio Diesel

Hemp biodiesel is made from hemp seed oil and can be used in any conventional diesel engine. University research showed hemp oil had a 97% conversion rate into biodiesel and passed all lab tests. Imagine a fleet of transport trucks powered by fuel made by a plant which left the soil in better condition than it found it.

Hemp can be used to make biofuels (the term given to fuels made from plants), called bioethanol and biodiesel. It can also be used as a fuel in a biomass power plant. Biofuels can be made by using both the fruit and grain of a plant or the fibres of the plants (cellulosic ethanol)

Biofuels have the advantage of being much more sustainable. This is because we can continue to grow and harvest the materials to make biofuel at a sustainable rate. But what makes hemp particularly suited to being used for fuel?

The majority of biofuel is currently made from corn or sugarcane. These are great sources of ethanol, as they contain a lot of sugar. However, the downside to using these crops is that it creates competition with food production. To create fuel from these plants, you are using material which could otherwise be valuable food.

In comparison, the leaves and cellulose fibres from the hemp plant are not valuable food sources. Having said this, the seed by-products from the plants can be used to make nutrient-rich food products.

Hemp can also be grown fairly easily, in most climates (unlike corn and sugarcane). This means that most countries around the world would have the ability to grow their own fuel. The crops also don’t usually require pesticides and herbicides, and reach maturity within four months – meaning that more biofuel can be produced more quickly.